手作業の場合、50Mロール1本をカットするのに4〜5時間かかりますが、ZUNDだと1〜2時間で終了できますし、休憩無しでカットし続けてくれるので、相当な時間短縮に繋がっています。

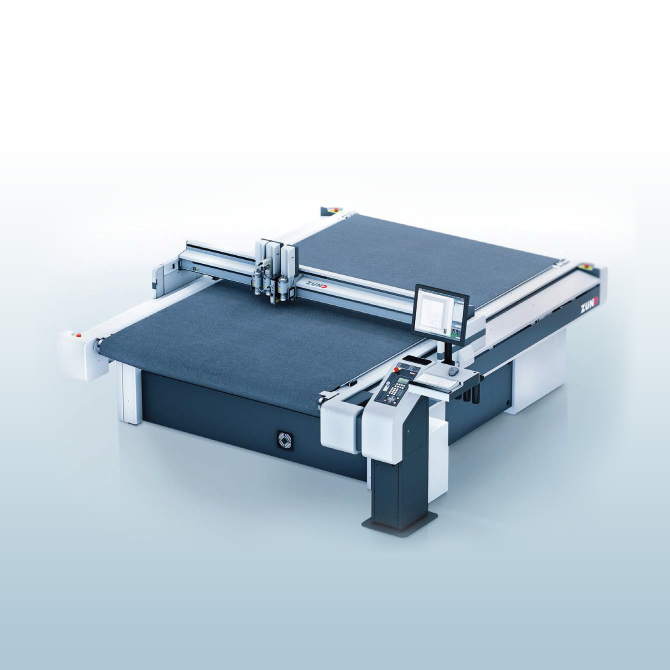

ズンド(Zünd) Zünd G3 Cutter

ズンド(Zünd) Zünd G3 Cutter

ナイフによる切断、エンドミルによる切削など厚み50mmの加工に対応した、妥協のないパフォーマンスと精度を誇るサンプルカッター(多機能サンプルカット機)。

業種・用途

屋外・サインディスプレイ

ソフトサイネージ(旗・のぼり・幕)

インテリア(壁紙・店内什器・窓ガラス)

印刷・ポスター・POP

包装(紙器・段ボール)

動画でみるZUND Cutterシリーズ

スペック

| 項目 | 概要 |

|---|---|

| 製品名(型番) | Zünd G3 Cutter |

| メーカー名 | ズンド(Zünd) |

| 最大加工厚 | 50mm(オプション110mm) |

| 最高速度 | 1,414mm/s |

| 最高加速度 | 9.3m/s2 |

| 反復精度 | ±0.03㎜ |

| 電源 | 三相208v、50/60Hz、20A |

| サイズ展開 | 【M-1600】幅1,330mm×長さ1,600mm 【M-2500】幅1,330mm×長さ2,500mm 【L-2500】幅1,800mm×長さ2,500mm 【L-3200】幅1,800mm×長さ3,200mm 【XL-1600】幅2,270mm×長さ1,600mm 【XL-3200】幅2,270mm×長さ3,200mm 【2XL-1600】幅2,740mm×長さ1,600mm 【2XL-3200】幅2,740mm×長さ3,200mm 【3XL-1600】幅3,210mm×長さ1,600mm 【3XL-2500】幅3,210mm×長さ2,500mm 【3XL-3200】幅3,210mm×長さ3,200mm |

製品の特徴

ナイフによる切断、エンドミルによる切削など厚み50mmまでの様々な加工に対応した、妥協のないパフォーマンスと精度を誇るスイス製カッティングマシン。

■モジュラーツーリング

Zündは様々な素材に適したツール/モジュールが存在します。全てのツール/モジュールは納入後でも追加可能で、ビジネスの展開に合わせ機械仕様を変えていくことができます。

■誰にでもZündを動かせるオペレーションソフトウェア(Zünd Cut Center・ZCC)

純正オペレーションソフトウェアであるZünd Cut Center(ZCC)を使用すればもう機械操作は心配ありません。広範囲な素材を登録済みのデータベースがあり、ユーザーは素材の選択をするだけで適切なツールとパラメータを簡単に呼び出し、すぐに生産に移る事が可能です。

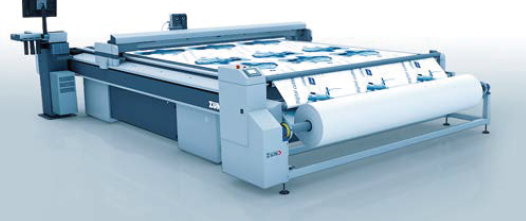

■オートロールハンドリング

Zünd Center Winderのヘビーデューティ設計により、100kgまでの加工ロールがセット可能です。洗練されたダンサーシステムは、一定の素材張力を保証します。 最も難しいテキスタイルでさえ、シワや過度のストレッチなしで機械に供給されます。

巻き戻しに加えて、モーター駆動のセンターワインダーを使用して、材料を巻き戻してロールに戻すことができます。

■統合されたツールの初期化

素早く正確に時間の節約:ナイフ、ルーター、折り目付けホイールの設定は、完全自動初期化システムを介して行われます。 カット深度を決定する手動調整作業はもはや必要ありません。

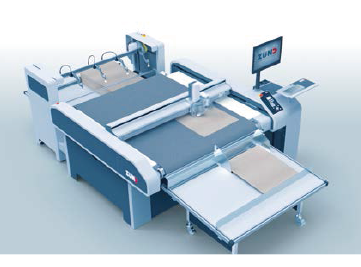

■完全に自動化されたシート/ボード処理

シートフィーダーを使用すると、G3/S3カッターを完全自動化生産システムにすることができます。 ビニールや高密度のカードボード材のシートを真空グリッパーでピックアップし、セットテーブルからカット面に移します。

処理後、機械はカットされた材料と廃棄物をオフロードテーブルに前進させます。 特に大規模な業務では、この自動化されたワークフローにより、効率的な生産を行う事ができます。

同シリーズ・関連製品

| 型番 | 仕様 |

|---|---|

| Zünd S3 Cutter | 最大加工厚:25mm/最高加速度:14.1m/s2 |

この製品の導入事例

-

車両マーキング / 屋内・屋外サイン / 標識・標示 / 外装・内装 / 環境・省エネ商品 デコラティブシステム株式会社 様

車両マーキング / 屋内・屋外サイン / 標識・標示 / 外装・内装 / 環境・省エネ商品デコラティブシステム株式会社 様

-

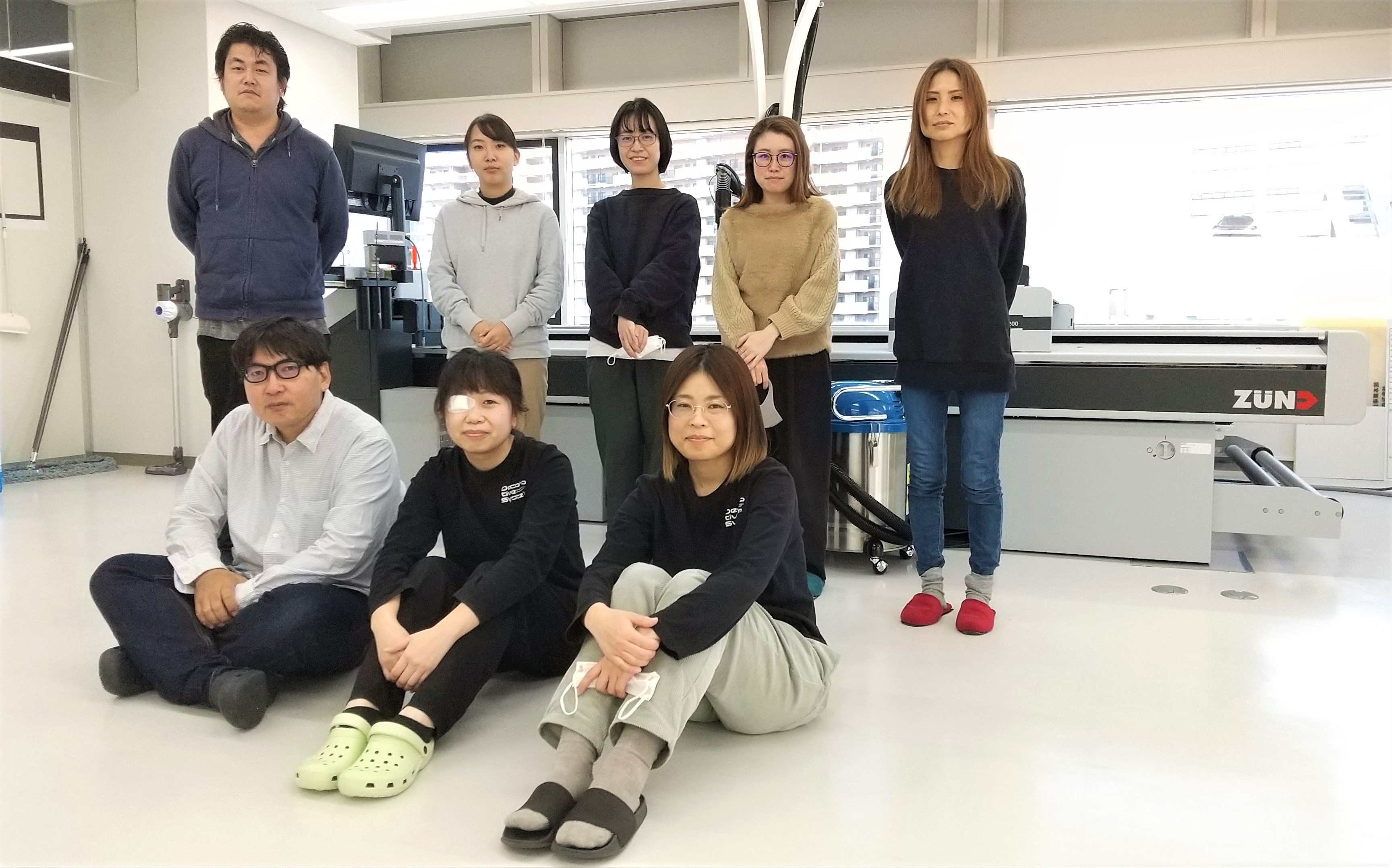

空間デザイン 株式会社アートフリーク 様

空間デザイン株式会社アートフリーク 様

ZUNDを導入してから、圧倒的に内製化が進みました。

-

印刷加工(サイン・ディスプレイ・店舗販促物等のデザイン、製作) 株式会社テイクコーポレーション 様

印刷加工(サイン・ディスプレイ・店舗販促物等のデザイン、製作)株式会社テイクコーポレーション 様

今まで手切りでしていた薄い梱包材料のカットも、定型サイズでたくさん一度に切ることで事前に用意でき、無駄の削減につながっていると思います。

製造メーカー

セルカムの売れ筋商品

-

エプソン(EPSON)|SC-S9150

-

ローランド ディー.ジー.(Roland)|TrueVIS XP-640

-

日本ヒューレットパッカード(HP)|Latex 630

-

ミマキエンジニアリング(Mimaki)|JV330-160

-

ローランド ディー.ジー.(Roland)|Versa OBJECT MO-240

-

ズンド(Zünd)|Zünd G3 Cutter

-

ローランド ディー.ジー.(Roland)|TrueVIS LG-640

-

ネーシェン社(NESCHEN)|Hotlam1650TH

-

フォトバ(FOTOBA)|XLA170

-

コーニットデジタル社(Kornit Digital)|Avalanche PolyPro